Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Raptor"

“Better to have, and not need, than to need, and not have.”

--Franz Kafka

Writer, 1883-1924

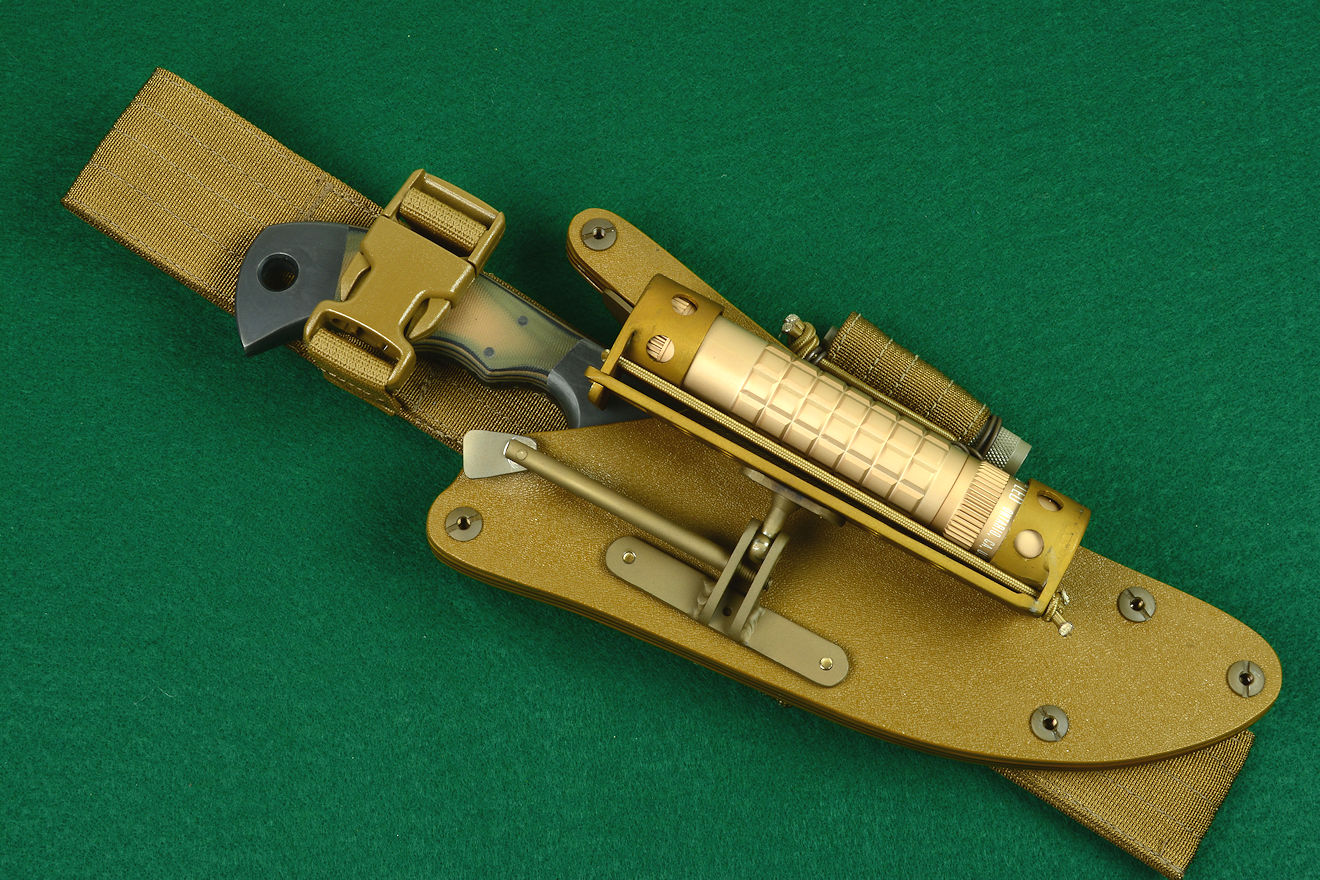

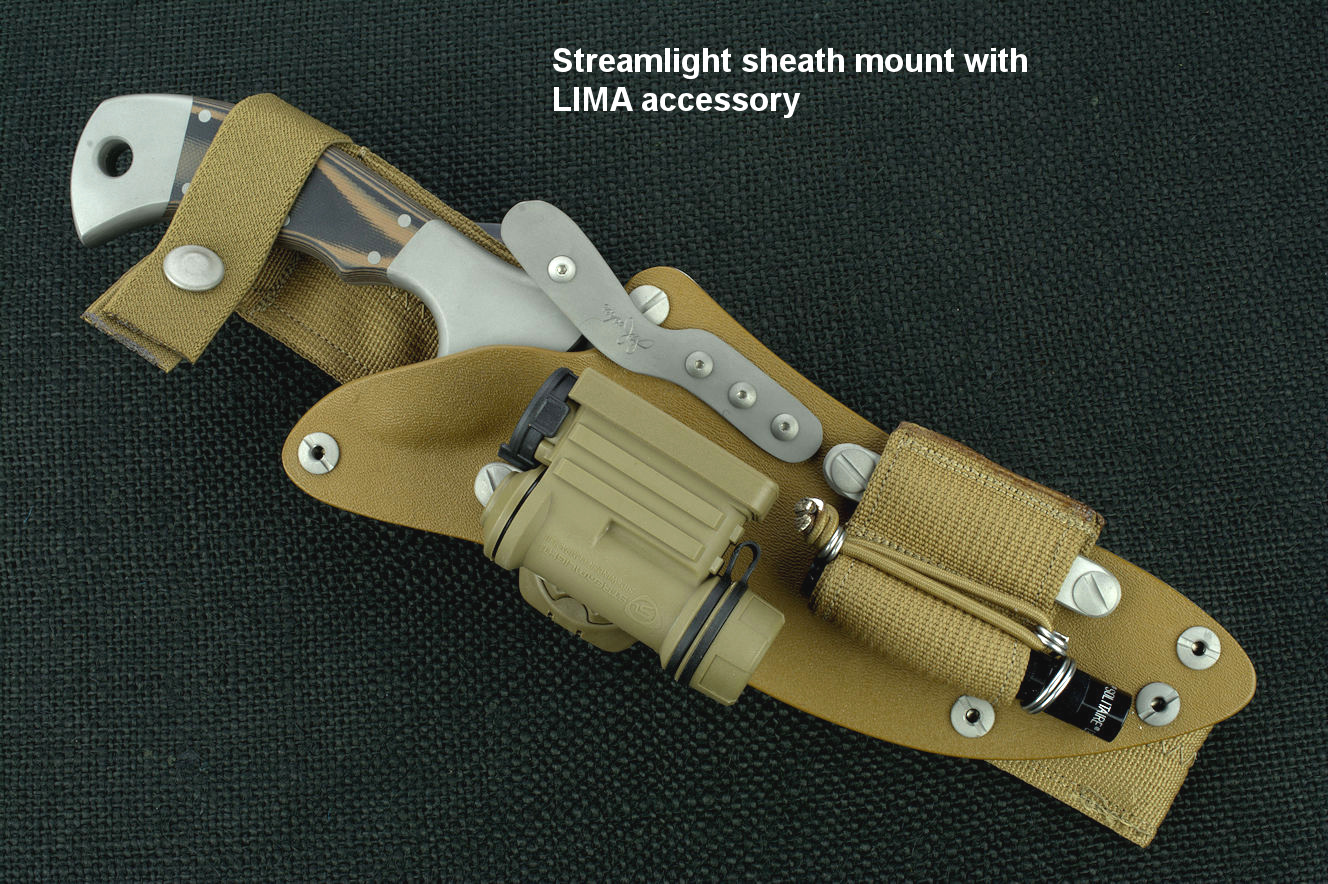

Many years ago, I saw the need for a small lamp to get the knife wearer home, to help add a bit of light to a dark area, to have a small flashlight to be able to look into a dark hole, retrieve something in a dimly lit place, or just to have an emergency source handy. This was the birth of the LIMA, the "Lamp, Independent Mount Assembly" that has accompanied most of my tactical knives since the early 2000s. You can read more about the LIMA on it's dedicated page.

Several military clients asked if it would be possible to provide a "key" lamp; a lamp that was not the small, emergency backup light that was provided in the LIMA, but a main, key lamp that would be the primary source for illumination for all of their excursions in tactical, rescue, or combat use.

Because knifemaking includes making and providing all of the accessories associated with the knife, and because the LIMA was so well-received and appreciated, I took a closer look at some of the problems I might be able to solve for the knife (and flashlight) owner and user.

Some might think that two flashlights is overkill, that a flashlight has no place in the knife kit, but I (and my clients) think differently. In order to effectively use a knife in a tactical situation, you need to see what you are cutting. The knife is (or should be) a razor-keen edged tool and weapon in the right hands. Nowhere is illumination more important, since the blade point and edge can and should pierce and cut everything they touch. Using an aggressive tactical knife with precision is not something done blindly.

My counterterrorism clients assure me that, no matter how well-made a flashlight is, it can fail, since it is an electrical device. You really can't say that about a well-made knife, since it's an object with no moving parts— a form that is fixed. My counterterrorism professionals claim that one flashlight is no flashlights, and two flashlights are only one flashlight, since backup is a critical necessity. This is another reason to have two lamps in the kit.

The HULA is the device that completes the primary lamp, while the LIMA fixes the backup lamp to the kit.

Typically, a tactical flashlight (or torch) seems to occupy five spaces on the professional. The belt holster, the head-mount, the clip mount, the firearm-mount, and the hand-carried.

These are the reasons I created the sheath-mounted HULA.

In the previous section, I detailed why there are so many issues with flashlights. They take up space, sure, but not much. The main issue with flashlights is that they take up your hands, or real estate on your rig, your body, your pack, frame, or even on your weapon.

This, then, is the issue. For a flashlight to illuminate a scene, it has to either have an incredibly wide field of illumination (without much reach) or it has to be held and aimed. This is the reason that the "A" (for "Articulating") is so important in my design of the HULA. The light can be aimed where needed, stay there fixed to a solid sheath mounted to your body, and operated, moved, and repositioned when and where needed.

You don't have to unclip, relocate, re-clip, mount, or grip the light. You just nudge it into place, and it stays there. I have professionals who have counted on the HULA in combat, even mounted on my Extended Length Belt Loop Extender, aiming and illuminating from their knife sheath mounted on the thigh.

IN COMBAT.

The HULA (Holder, Universal, Lamp, Articulating) is designed to mount on my tactical, counterterrorism, combat, rescue, and survival knife sheaths to store, hold, and aim a primary flashlight. It has an articulating and wide range of adjustment. It allows the user to aim the flashlight, and lock it in that position. It can be rigidly locked in that position, or lightly locked, allowing easy movement, or completely released, allowing free movement and aiming. It can be folded and moved to the side, front, or even rear of the sheath.

The flashlight is quickly and reliably removed from the HULA with one hand, even without looking. The device has versatile wear and location options, all along the sheath welt frames. It's also extremely corrosion-resistant requiring no care. It's extremely strong.

The professional user of the tactical combat knife doesn't need to worry about corrosion; he's got enough on his mind. The knife shouldn't corrode, neither should the sheath, neither should any component or accessory that interfaces with them.

To solve this problem, I use all stainless steel in the higher strength and wear areas of the HULA. This starts with the mounting screws, which are standard in all my kits. They are 8-32 UNC standard thread machine screws. They are Chicago Screws (male-female sex bolts), Socket Head Cap Screws (SHCS) and Button Head Cap Screws (BHCS). They are all made of 304 high nickel, high chromium austenitic stainless steel. This is also called 18-8 stainless steel, the standard in the field for stainless nuts, bolts and fasteners.

The machine screws fasten to drilled and tapped threaded bars on the HULA frame. The HULA frame is also made of 304 stainless steel (18-8 SS), and is fully welded in a high purity process, by hand. The frame is mounted to two tabs that accommodate the ball of the ball joint.

The ball, tabs, and shaft are all 304 stainless steel as well. This assures that wear of the ball is minimal, and the pinch bolt can squeeze the tabs together and solidly grip the ball, to lock the HULA where the user wants it. The pinch screw is also stainless steel, and may be topped with a tab-pad for the fingers that is either 304 stainless steel or 6AL4V titanium. None of this will corrode, rust, or degrade, ever.

The flashlight holder and frame encounters less wear, and needed to be lighter but strong, so I make these in 5052 H32 high strength, corrosion-resistant aluminum alloy. This is not simple aluminum; it's aluminum with chromium, magnesium, silicon, and manganese. 5052 aluminum is the highest strength alloy of the non-heat-treatable grades. Its resistance to fatigue is better than most grades of aluminum. Alloy 5052 has a good marine atmosphere corrosion resistance of saltwater and excellent workability. 5052 is used for fan blades, utensils, and even fuel tanks. It's also used to make ladders, frames, and railings. This is good stuff.

Like my LIMA accessory, there is only one component that can wear, so I made these as simple as possible. That component is the bungee cord, or shock cord that pulls the flashlight into the frame and secures the tail cap. I wanted my clients to be able to easily replace this as needed, to adjust the tension to their preference, and I wanted it to be commonly and easily acquired at any hardware store or internet source. This is why I chose simple 1/8" shock cord and a few overhand knots in the design. No rubber to oxidize and wear, no specialized shape or plastic cast forms, no clips or springs or Velcro® to wear out, make noise, or be a hassle to replace. Like the LIMA, when the owner starts to see wear and the white of the cord interior, it's time to replace it. If it loses its elasticity, it's time to replace it. Uncomplicated, inexpensive: fixed.

That's it: three materials, four parts total, not counting the machine screws. Simple, sturdy, logical

My early HULAs were simply media-blasted. This stopped any reflective surface and glare that would telegraph a location to an enemy, and the flat finish went with the flat, blasted appearance of the sheath welts. When I started making advanced counterterrorism knives, clients requested all-black or all-coyote models, non-reflective, and flat black finishes in all the gear.

At the time of this writing, I make most of my gear in black, followed by coyote.

The stainless steels are blackened by an etching and oxide process; they are still stainless, but are darkened to a shadowy gray-to-black appearance. Similar to bluing, this is a surface oxide and part of my "Shadow" line of knife gear, specifically but not only suited to counterterrorism and combat tactical knives. The coyote brown or straw brown stainless appearance is a heat oxide process that permanently colors the surface of the stainless without sacrificing any corrosion resistance.

To get the colors on the aluminum was another entire process, called anodizing. In anodizing, a near-ceramic hard surface is created that has microscopic pores that can be filled with colorfast dyes, and sealed with sunlight and UV light-resistant surfaces. This is the only way to make aluminum corrosion-resistant, even in high temperature, highly acidic or alkaline or salty exposures. Anodizing requires a complete and accurate process, with immersion baths, chillers, etchants, deoxidizers, dye baths, and high temperature sealants. It results in a hard surface, extremely durable an abrasion-resistant, and permanent intense color. I perform that entire process here in my studio.

I use anodizing in all my sheath parts and accessories now. The belt loops, plates, straps, and clamps are anodized, as are the welts of the sheaths themselves, inside and out. Incidentally, it's the same process used to coat and color the flashlights, only my application is typically twice as thick.

Could I make these all in bright red? Why yes, of course! And orange, and blue, and pink... okay, nobody has requested this yet, so I have no pictures to show you-

The HULA is completely intuitive. You tighten the ball lock enough for some resistance, and it will have a bit of break-in, and then will have a "sweet" spot of tightness where you can just position the light with your hand and it will stay there. If you plan on running, or highly active motion, you can tighten it up a bit and it will stay locked in position. If you want the flashlight to remain vertical, at the side of the sheath, rigid and immovable, just position it there and tighten the pinch bolt. There's not a lot to aiming the device, no dual axis and rotation, just point and lock if desired.

To mount the HULA in different positions, just figure out where on the sheath you want it. My sheaths all have a 2.5" machine screw center distance that is standard, and on most parts of the sheath, but not every hole, since the sheaths vary so much. Some of the sheaths may have shorter "mouth" screw spacing and shorter "tail" screw spacing depending on the pattern of knife. Be sure that the holes line up, and you're good to go. Start the screws by hand, with fingertips only, so you don't cross-thread the stainless. Stainless steel is very unforgiving about cross-threading, so be careful here and don't ever force a screw. once it's started, you're golden.

The screws don't need to be tight as a wheel on a race car, just snug is good. Hex keys are included to do this. You may have to back up the screw head with a flat blade screwdriver, but that's easy enough.

To take the flashlight out of the HULA is even simpler; I've made a "T-slot" lock that is easy to see in the photos. I made these big enough to be able to "feel" in the dark. I don't want my clients to have to struggle with the mechanism, so it's simple and can be felt with the fingertips alone, even in gloves. This way, a simple touch will assure you that the flashlight is in place, and the T-slot is secure.

Once the flashlight is removed, I recommend re-mounting the cap lock in the T-slot. This will make sure that it won't hang on anything, won't rattle, and won't get in the way. After a client becomes familiar with the device, he can usually do all this with one hand, in the dark, by feel alone.

Most of the flashlights are operated with a tail switch, but some have a side switch on the barrel, and some have both. It depends on the model. There is a clear hole on the cap of the HULA that allows tail cap operation.

All I can recommend is keep the heavy mud out of it. No oil needed, no screw adjustment, just hose off if needed, and make sure the shock cord is not fraying or wearing out. If it is, replace it ASAP. Just a couple overhand knots is all the skill required, get it as tight as you like it, but not too loose, or you'll lose your flashlight. You can melt the ends to stop fraying with a lighter if you like.

By the way, if you lose your flashlight, there are a whole group of lights that will fit it. Look for the specs on the flashlight, because the vendors who sell these will give the length and diameter of both ends.

On my older page on this, I gave specific model information, type, manufacturer, and detailed all the specifications of the flashlights: lumen output, range, water resistance, battery type, all of that stuff. Flashlight technology has moved very fast in the last ten years, and there are a whole range of flashlights that have many new features, much more intense LED technology, and many new programming features have been added. Technological advances aside, the aiming and holding potential will always rely upon a simple, universal device that is operated and locked by the human hand alone. Even if a flashlight has a "candle," "strobe," "color-changing," or "dance music disco-ball" function, it will still need to be held either by a human hand or by an aiming device.

Rather than stick to a specific type and stagnant vendor of these flashlights, I currently make a variety of HULA accessories that use a variety of lights. For instance, I found that although Maglite makes some good, sturdy and simple lamps, they don't have the light output that some of my clients request. Or, they aren't programmable. Or rechargeable. Some of my clients don't want rechargeable lamps; some do. Some want a variety of battery choices, and the newer lamps offer this. Some stick to the theme of "American Made," even though Maglite hasn't been entirely American made for over 20 years. But I still offer Maglite flashlights on some models, because they are very sturdy.

I also offer some of the latest incredibly intense lamps, and I've included lamps with the kits that have been now upgraded to even more new models. The thing is, I've never known anyone who has "worn out" even one of these, only lost them.

So I offer a variety of flashlights. The important thing about the newer lamps is that you're unlikely to ever wear them out. LED technology offers "bulbs" that have 50,000 to 100,000 hour life, and even if they start to go bad, they just get a little dimmer. If you use your flashlight for three hours every single night, you'll be starting to worry about your flashlight after a 45-90 year career. Really. I have LED lights that will literally outlast my grandchildren. Life has certainly changed since the incandescent bulb.

By the way, I started making the LIMA with incandescent lamps and upgrading them to LED "bulbs" when I started making these kits. Yep, I couldn't find a tiny LED lamp when I started! That should tell you how long I've been at this...

Every flashlight I include with the kit will have all the paperwork and specs with it. And since the size of the HULA is generalized for the 4-5" length and 1" diameter range of flashlights, even if you lose it, you'll be able to find another that will fit the HULA, just measure it first.

Yes, I've made those. When some clients required IR safe lights for night vision operation, I was limited to the flashlights that would do that for them. I used Streamlight flashlights for that particular setup. While the rotation and aiming was somewhat limited by the flashlight itself, I was happy to be able to do this for specific clients in this application.

If you have a custom need like this, I will consider it, and can probably work it out. After all, this is a custom affair, made to order, and bespoke projects still fill my lists.

Just don't ask for a disco ball or moonbeam laser and particle accelerator. I've got enough backlog as it is...

The HULA I make for my tactical combat and counterterrorism knife kits is the finest made in the world.

That's a pretty big statement, and I'm sure that at this point in the page you now know why.

Please understand that there is NO viable, durable flashlight holding and aiming mechanism that even comes close. Most flashlight aiming devices are built into the plastic of the flashlight itself, and some are somewhat useful, but all are limited.

For instance, Streamlight® in the previous topic makes a pretty intuitive device for their helmet-mounted lights, but it has some obvious flaws. At the time of this writing, they are found in the "Sidewinder" line, and I've used these myself when clients have requested them. The problem with all "in-device" aiming mechanisms is that they are made of the same weak plastic that the flashlight is made from. Plastic, after all, will wear, is not strong and is not durable, nor is it expected to be. Wear it out, and you'll just buy another... and another, and-

Another problem is that because they are made of plastic, the flashlights are very small, with limited, even dim light output. They have to be; there isn't enough strength in them to hold a sizable battery set, yet mount and move easily. The Streamlight Sidewinder, for example, only puts out 55 lumens. Contrast this with the early Mag-Tacs that put out 320 lumens.

Even more dramatic, in the 2020s, hand-sized lamps that fit the HULA put out 1300 lumens (PowerTac®). Even the tiny ThruNite T3 I use for the LIMA puts out over twice as much light as the Streamlight at 120 lumens!

Let's look at this a bit further. The PowerTac E9R puts out 2550 lumens, over 46 times as much light as the Streamlight! Incredible advances like this in LED and battery technology are bound to continue, but the thing that never changes is the knife, the sheath, and the human hand size to comfortably hold the flashlight. This is why the HULA is designed at this size and shape range.

The neat thing about these modern lights is their programmability. They can be programmed to an array of lower power settings, and in some cases, this leads to a battery life of 50 days. Yes, I wrote that correctly, and they are waterproof and submersible.

My HULA is a permanent device, made to fit a variety of flashlights. The flashlights it fits are metal-cased; they are all made of tubular aluminum alloy, anodized and knurled, textured, and often waterproof. If (and when) the flashlight is broken, or is lost, or fails, or just gets old, the aiming holder of the HULA will still accept a new flashlight, still aim, still work, and will absolutely outlast the owner of the knife! It's not going anywhere because, when used, it's attached to the knife sheath with solid stainless steel machine screws.

The HULA is durable because it's built of stainless steel and high strength aluminum alloy. Any wear of the adjustment is simply taken up by tightening the pinch bolt. Any wear or the retention device requires only a simple replacement of some bungee cord, plentiful at every hardware store or internet supplier from Wal-Mart® to Amazon®.

Humorously, one uneducated forum participant saw the photos of the HULA and thought it looked "weak," stating that if the wearer took a tumble, that it might bend or break. This shows the ignorance of people who base their opinions on plastic. If it was made of plastic, it might well bend or break, but the HULA is made of stainless steel and high strength aluminum alloy. The sheath welts would bend and the sheath kydex would fracture before the HULA would be damaged, and if the wearer suffers enough to do that, he will have other major trauma problems! The stainless steel won't bend, the aluminum won't break, and in the hundreds of these I've made over several decades, I've not had a report of a failure or even a problem of a single one, not one!

I want this to be very clear. There is only one. The HULA is not cheap. This is the reason you won't see it on any other application in this field or any other.

Just like my knives and specialized accessories, it's the very best made, and it can't be manufactured for cheap, can't be made of injection-molded plastic, can't be copied by foreign manufacturers. No company that makes and sells cheap knives is going to make a flashlight holder that costs more than their flashlight, and more than their knives, so I don't expect any competition.

That's okay, I'm not out to mass-market the HULA, only to supply the very best flashlight holder possible for my tactical counterterrorism and combat knife kits and the people who use them.

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | Military Knife Care | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | |

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |